The interlock contacts installed in the previous section's motor control circuit work fine, but the motor will run only as long as each pushbutton switch is held down. If we wanted to keep the motor running even after the operator takes his or her hand off the control switches, we could change the circuit in a couple of different ways: we could replace the pushbutton switches with toggle switches, or we could add some more relay logic to "latch" the control circuit with a single, momentary actuation of either switch. Let's see how the second approach is implemented, since it is commonly used in industry:

When the "Forward" pushbutton is actuated, M1 will energize, closing the normally-open auxiliary contact in parallel with that switch. When the pushbutton is released, the closed M1 auxiliary contact will maintain current to the coil of M1, thus latching the "Forward" circuit in the "on" state. The same sort of thing will happen when the "Reverse" pushbutton is pressed. These parallel auxiliary contacts are sometimes referred to as seal-in contacts, the word "seal" meaning essentially the same thing as the word latch.

However, this creates a new problem: how to stop the motor! As the circuit exists right now, the motor will run either forward or backward once the corresponding pushbutton switch is pressed, and will continue to run as long as there is power. To stop either circuit (forward or backward), we require some means for the operator to interrupt power to the motor contactors. We'll call this new switch, Stop:

To be continue in Part II

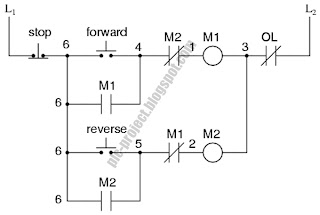

Figure 1

When the "Forward" pushbutton is actuated, M1 will energize, closing the normally-open auxiliary contact in parallel with that switch. When the pushbutton is released, the closed M1 auxiliary contact will maintain current to the coil of M1, thus latching the "Forward" circuit in the "on" state. The same sort of thing will happen when the "Reverse" pushbutton is pressed. These parallel auxiliary contacts are sometimes referred to as seal-in contacts, the word "seal" meaning essentially the same thing as the word latch.

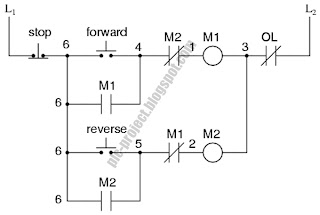

However, this creates a new problem: how to stop the motor! As the circuit exists right now, the motor will run either forward or backward once the corresponding pushbutton switch is pressed, and will continue to run as long as there is power. To stop either circuit (forward or backward), we require some means for the operator to interrupt power to the motor contactors. We'll call this new switch, Stop:

Figure 2

To be continue in Part II

0 comments:

Post a Comment